Project owner

City of Waidhofen an der Ybbs

Architect

Tragwerkstatt Ziviltechniker gmbh

Engineers

Tragwerkstatt Ziviltechniker gmbh

AXIS Ingenieurleistungen ZT GmbH

Steel contractor

RW-MOntage GmbH

In the summer of 2014 the municipality of Waidhofen an der Ybbs decided on replacing the existing Ybbs bridge with a new structure. The tender was won by the project “Schlosssteg 2.0” by the project partnership Schlosssteg 2.0 (GLS Bau und Montage GmbH, RW-Montage GmbH) and the design team of Axis ZT GmbH and tragwerkstatt ZT gmbh. Following an intense design phase, construction started on June 24, 2015, and was finished on October 21, 2015.

Schlosssteg 2.0 was designed as a steel construction, since this construction type allows for the quickest construction time whilst reducing the environmental impact to a minimum. Moreover, no other construction type permits such a slender construction, which was a decisive factor in embedding the bridge in its environment.

Bridges unite and expand our world, just as Schlosssteg 2.0 connects the two municipalities of Waidhofen and Zell, expands the sphere of many inhabitants and constitutes a key element in developing a city with short walking distances. This last aspect could also be complied with by manufacturing the bridge elements in the yard of RW-Montage, just 45 km away from the construction site.

Waidhofen an der Ybbs, once a centre of metallurgy and member of the Iron Road, has a long tradition in iron and steel. Still today, the region has numerous metalworking companies. In this context, using steel was not only obvious but even contributed to identity generation. Schlosssteg 2.0 is manufactured of weathering steel, takes up the “Genius Loci”, harmonically blends in the historic ensemble and contributes essentially to the local construction culture.

By manufacturing close to the construction site the principle of short distances could be literally applied. Since many components could already be prefabricated, the complete Schlosssteg was transported to site by just six flatbed trucks. In order to reduce the environmental impact and to keep the usage of new material low, the existing abutments of the old bridge were reused and just adapted to fit the new structure.

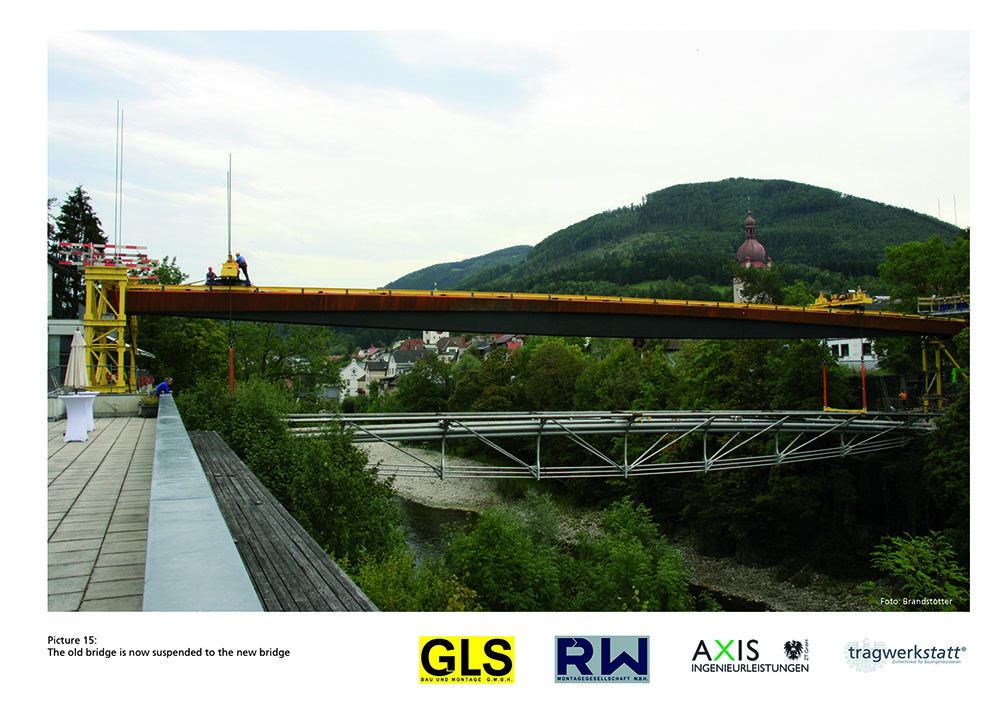

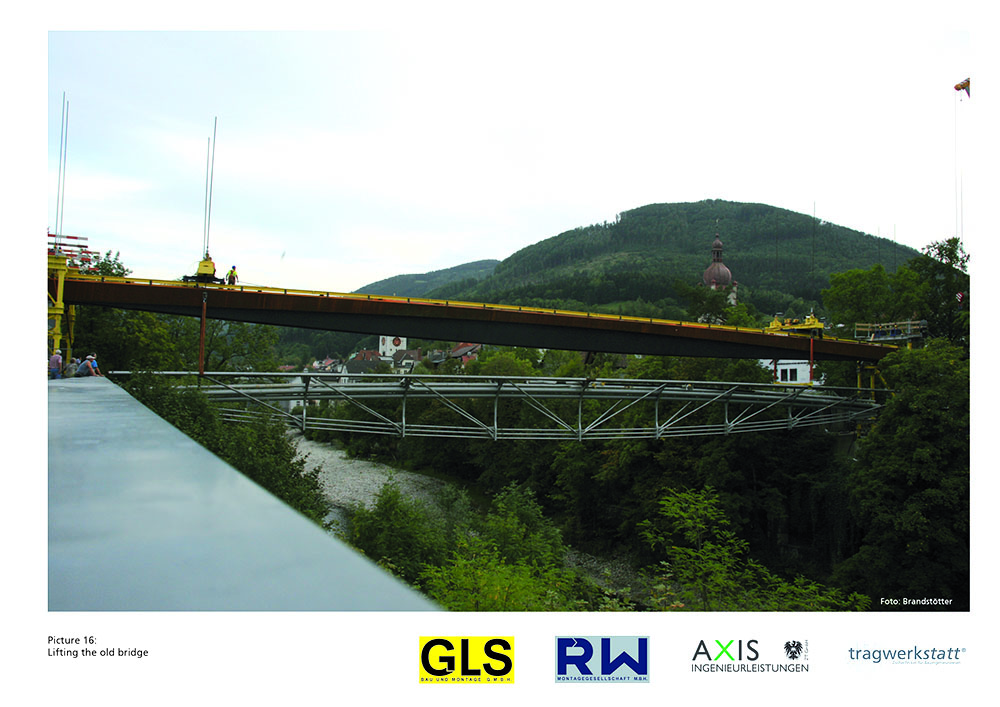

Already during the design phase an optimised construction concept was custom-tailored to the local requirements, incorporating the existing bridge in the installation of the new bridge. Hence, the complete installation could be carried out “from above”. It was not necessary to intrude on the sensitive riverbanks of the Ybbs. This “non-invasive” installation method allowed for the smallest possible impact on the environment.

Design and Material Concept

Well-proportionate shapes create elegance. In bridge construction, this is achieved by slender structures. Schlosssteg 2.0 has two main and two edge girders with different surfaces. The edge girders are of raw weathering structural steel, which develops an optically appealing umber patina, and does not require any maintenance work during its entire service live. The edge girders form the “visual interface” and let the eyes of the beholder smoothly glide over the Ybbs.

The two main girders, however, form the static backbone of the construction and are therefore higher than the edge girders. To optimise visual slenderness, the edge girders are in front of the main girders, making the main girders virtually disappear in the shadows. The main girders were painted dark grey to increase this effect. The railings are those parts that are directly touched by the bridge users; therefore they were made of stainless steel. Moreover, no corrosion protection was required for the railings, creating a durable and low-maintenance construction.

Another innovation was the filling of the main box girder with quartz sand at dynamically favourable positions, which was already taking into account in the statics calculations. This solution could be used to reduce vibrations caused by pedestrians. Therefore, it was not required to apply expensive tuned mass dampers.

Installation Concept

The erection of the new Schlosssteg included the deconstruction of the existing structure while maintaining the existing power lines and district heating ducts. Moreover, during the complete process, special consideration was put on the environment, due to natural monument and preservation reasons.

By consistently implementing a holistic design strategy, all these - partly contradictory - requirements could be met. In particular the process of erecting the new and the deconstructing the existing structure were taken into account in designing the new bridge right from the beginning. A “non-invasive” installation concept was developed already at a very early project stage. To this end, the existing structure was incorporated in the installation of the new bridge, and - vice versa - the new bridge was used to remove the old one, resulting in a unique construction concept running like a thread through all project phases and eventually reflecting the uniqueness of the new Schlosssteg at large.

Professor J.M. ROTTER was born in Chesterfield, England and graduated at Cambridge University when he was awarded a Commonwealth Scholarship to study in Australia. He got a PhD in civil engineering from the University of Sydney. His main specialty is the Buckling of Shells.

Professor J.M. ROTTER was born in Chesterfield, England and graduated at Cambridge University when he was awarded a Commonwealth Scholarship to study in Australia. He got a PhD in civil engineering from the University of Sydney. His main specialty is the Buckling of Shells. Jouko KOUHI is expert in Connections, welding, stability and fatigue of steel structures. He has been an active member of various ECCS Technical Committees since 1979, working on ENV 1993 part 1.8 from 1999 to 2002.

Jouko KOUHI is expert in Connections, welding, stability and fatigue of steel structures. He has been an active member of various ECCS Technical Committees since 1979, working on ENV 1993 part 1.8 from 1999 to 2002. Frans BIJLAARD, Professor of steel structures at the Faculty of Civil Engineering & Geosciences at Delft University of Technology. His main specialties are on stability of steel structures, structural behaviour of joints in steel structures and design of greenhouses.

Frans BIJLAARD, Professor of steel structures at the Faculty of Civil Engineering & Geosciences at Delft University of Technology. His main specialties are on stability of steel structures, structural behaviour of joints in steel structures and design of greenhouses. The involvement of Professor Jean Pierre MUZEAU in Education and his strong motivation in promoting the use of steel in construction over his career have to be underlined. He has been qualified as “Passeur de Connaissances” (Ndt : conveyor of knowledge) by the Members of the Jury who have underlined his prominent role among the young generations of civil engineers.

The involvement of Professor Jean Pierre MUZEAU in Education and his strong motivation in promoting the use of steel in construction over his career have to be underlined. He has been qualified as “Passeur de Connaissances” (Ndt : conveyor of knowledge) by the Members of the Jury who have underlined his prominent role among the young generations of civil engineers. Prof. Joachim LINDNER got a 40-year academic career and extensive experience in civil engineering from lateral torsional buckling through contact splices, historical grey cast iron columns, fatigue behaviour, stability design of glass-beams, scaffolding design, crane girders, plate buckling problems, composite beams and columns, corrugated webs, connection problems and imperfection regulations. He signed around 220 publications.

Prof. Joachim LINDNER got a 40-year academic career and extensive experience in civil engineering from lateral torsional buckling through contact splices, historical grey cast iron columns, fatigue behaviour, stability design of glass-beams, scaffolding design, crane girders, plate buckling problems, composite beams and columns, corrugated webs, connection problems and imperfection regulations. He signed around 220 publications. Professor Reidar BJORHOVDE has an impressive academic background, including two Ph.D. in the area of Civil Engineering, and a remarkable professional career which includes several years as a Professor in various universities in North America. He also been the Director of Bjorhovde Group since 1998.

Professor Reidar BJORHOVDE has an impressive academic background, including two Ph.D. in the area of Civil Engineering, and a remarkable professional career which includes several years as a Professor in various universities in North America. He also been the Director of Bjorhovde Group since 1998.

Professor Carlo URBANO has been active on ECCS committee “Stability of steel structures” since 1975. He has been also present on CEN, IABSE, SSRC committees. Graduated at the Politecnico di Milano in 1963, he dedicated his career to the “Strength of Materials”. He developed scientific research mainly on the general theory of elasticity, stability of elastic equilibrium, response to dynamics and elastoplastic vibrations, shell structures, solutions for steel and reinforced structures. Lately, he has focused his works on the elastic and elastoplastic stability of compressed simple or composed steel members in the presence of mechanical and geometrical imperfections and damages due to cyclic actions. He is the author of an incredible number of papers and publications.

Professor Carlo URBANO has been active on ECCS committee “Stability of steel structures” since 1975. He has been also present on CEN, IABSE, SSRC committees. Graduated at the Politecnico di Milano in 1963, he dedicated his career to the “Strength of Materials”. He developed scientific research mainly on the general theory of elasticity, stability of elastic equilibrium, response to dynamics and elastoplastic vibrations, shell structures, solutions for steel and reinforced structures. Lately, he has focused his works on the elastic and elastoplastic stability of compressed simple or composed steel members in the presence of mechanical and geometrical imperfections and damages due to cyclic actions. He is the author of an incredible number of papers and publications.

Prof. Ing. Jean-Baptiste SCHLEICH will always be recognised as "Mr Fire” of Europe. He was the leading professor in the development of the "Natural Fire Safety Concept". Under his leadership, the relationship of the fire load to the risk to a structure and its occupants was researched and tested. It is due to his work that structures can now be fire engineered with a significant benefit to the industry, building owners and users.

Prof. Ing. Jean-Baptiste SCHLEICH will always be recognised as "Mr Fire” of Europe. He was the leading professor in the development of the "Natural Fire Safety Concept". Under his leadership, the relationship of the fire load to the risk to a structure and its occupants was researched and tested. It is due to his work that structures can now be fire engineered with a significant benefit to the industry, building owners and users. Professor Manfred HIRT had been member of the various ECCS Technical Committees. He wrote more than 130 publications as author or co-author. Director of the Steel Structures Laboratory (ICOM) of the Swiss Federal Institute of Technology at Lausanne (EPFL), Prof. Hirt was known on the international scene for his expertise in the field of fatigue and fracture mechanics of steel structures, loads and action on structures, structural safety and serviceability and steel-concrete composite construction. In August 2003, he had been elected President of the International Association for Bridge and Structural Engineering (IABSE).

Professor Manfred HIRT had been member of the various ECCS Technical Committees. He wrote more than 130 publications as author or co-author. Director of the Steel Structures Laboratory (ICOM) of the Swiss Federal Institute of Technology at Lausanne (EPFL), Prof. Hirt was known on the international scene for his expertise in the field of fatigue and fracture mechanics of steel structures, loads and action on structures, structural safety and serviceability and steel-concrete composite construction. In August 2003, he had been elected President of the International Association for Bridge and Structural Engineering (IABSE). Professor Giulio BALLIO was born in Rome, on 4 March 1940, and graduated in Aeronautical Engineering at the “Politecnico of Milan”, in 1963. He was Ordinario of the Science of Construction at Pavia University and, subsequently, of Construction in Steel at the Politecnico of Milan, where he has also been responsible, since 1985, for the Material Tests Laboratory.

Professor Giulio BALLIO was born in Rome, on 4 March 1940, and graduated in Aeronautical Engineering at the “Politecnico of Milan”, in 1963. He was Ordinario of the Science of Construction at Pavia University and, subsequently, of Construction in Steel at the Politecnico of Milan, where he has also been responsible, since 1985, for the Material Tests Laboratory. Prof. Dr.-Ing. Gerhard SEDLACEK, was a leading and opinion-forming person in various ECCS technical committees and subcommittees. He was one of the most active person in the European steel research sector as well as in the European codification field. His various activities covered a huge range beginning from intelligent design of steel and composite structures to researching, applying of research results, safety requirements, teaching and training of students and engineers, promotion and developing of steel structures and design tools for a better market share.

Prof. Dr.-Ing. Gerhard SEDLACEK, was a leading and opinion-forming person in various ECCS technical committees and subcommittees. He was one of the most active person in the European steel research sector as well as in the European codification field. His various activities covered a huge range beginning from intelligent design of steel and composite structures to researching, applying of research results, safety requirements, teaching and training of students and engineers, promotion and developing of steel structures and design tools for a better market share. Professor Patrick DOWLING started his working life as an employee of BCSA and subsequently worked both in industry and academia. He was extensively involved with ECCS in plate buckling research and was Chairman of the CEN Eurocode 3 Committee.

Professor Patrick DOWLING started his working life as an employee of BCSA and subsequently worked both in industry and academia. He was extensively involved with ECCS in plate buckling research and was Chairman of the CEN Eurocode 3 Committee. When awarded, Professor Federico MAZZOLANI was Director of the “Institute of Technique of Construction” at the Engineering Faculty of Naples, Italy. Born in Milan, in 1938, and graduated in Civil Engineering at the University of Naples, Prof. Federico M. Mazzolani co-operated since 1970 with ECCS, assuming the responsibility of Committee chairmanship. His activity has been characterised by the issue of several fundamental documents, which played a leader role in the development of the European codification at the level of both national codes and Eurocodes.

When awarded, Professor Federico MAZZOLANI was Director of the “Institute of Technique of Construction” at the Engineering Faculty of Naples, Italy. Born in Milan, in 1938, and graduated in Civil Engineering at the University of Naples, Prof. Federico M. Mazzolani co-operated since 1970 with ECCS, assuming the responsibility of Committee chairmanship. His activity has been characterised by the issue of several fundamental documents, which played a leader role in the development of the European codification at the level of both national codes and Eurocodes. Scientific Manager and Deputy General Manager of the French Technical and Industrial Centre of Steel Construction (CTICM), Professor Jacques BROZZETTI contributed highly to the development of the European Steel Construction. He had a long involvement with various research projects including stability problems, composite construction, fatigue and fire behaviour of steel structures. As a result, he had been involved with many Codes and design guides comprising writing activities. He worked with the profession to promote the steel construction on its various aspects.

Scientific Manager and Deputy General Manager of the French Technical and Industrial Centre of Steel Construction (CTICM), Professor Jacques BROZZETTI contributed highly to the development of the European Steel Construction. He had a long involvement with various research projects including stability problems, composite construction, fatigue and fire behaviour of steel structures. As a result, he had been involved with many Codes and design guides comprising writing activities. He worked with the profession to promote the steel construction on its various aspects. Prof. Jan W.B. STARK, from the University of Delft, The Netherlands, had made substantial contributions to the construction industry in general, and more specifically with regard to steel and composite structures. For many years, he had been an active member of CEN and served ECCS in various committees. The Charles Massonnet Award was presented to him to express our gratitude for his high standard and valuable contribution to the steel construction industry.

Prof. Jan W.B. STARK, from the University of Delft, The Netherlands, had made substantial contributions to the construction industry in general, and more specifically with regard to steel and composite structures. For many years, he had been an active member of CEN and served ECCS in various committees. The Charles Massonnet Award was presented to him to express our gratitude for his high standard and valuable contribution to the steel construction industry. Close collaborator of Professor Charles Massonnet, Professor René MAQUOI, was awarded in recognition of his efforts for the development of steel and composite construction. Indeed, Professor Massonnet was his “master” and conducted his first step in the ECCS activities.

Close collaborator of Professor Charles Massonnet, Professor René MAQUOI, was awarded in recognition of his efforts for the development of steel and composite construction. Indeed, Professor Massonnet was his “master” and conducted his first step in the ECCS activities.

Frantisek Wald concentrates on the connection and fire design of steel structures. He prepared the component model for column bases and the component based finite element model of joints. He works in ECCS Technical Committee 10 - Structural joints and in Project team for preparation of standard - EN 1993-1-8:2020.

Frantisek Wald concentrates on the connection and fire design of steel structures. He prepared the component model for column bases and the component based finite element model of joints. He works in ECCS Technical Committee 10 - Structural joints and in Project team for preparation of standard - EN 1993-1-8:2020.