The EUROPEAN STEEL DESIGN AWARDS are given by ECCS every two years to encourage the creative and outstanding use of steel in architecture and construction. Outstanding design in steel construction emphasizes the many advantages of steel in construction, production, economy, environment and architecture.

This year, from the 18 projects submitted in total by the ECCS member associations for ESDA 2023, the international expert jury selected 11 nominees, one per country. The overall winner ESDA 2023 Laureate and two ESDA 2023 Special Awards were then chosen out of those nominees and announced during a reception on 12 September 2023 in Amsterdam, in the frame of the EUROSTEEL conference.

European Steel Design Award 2023 Laureate:

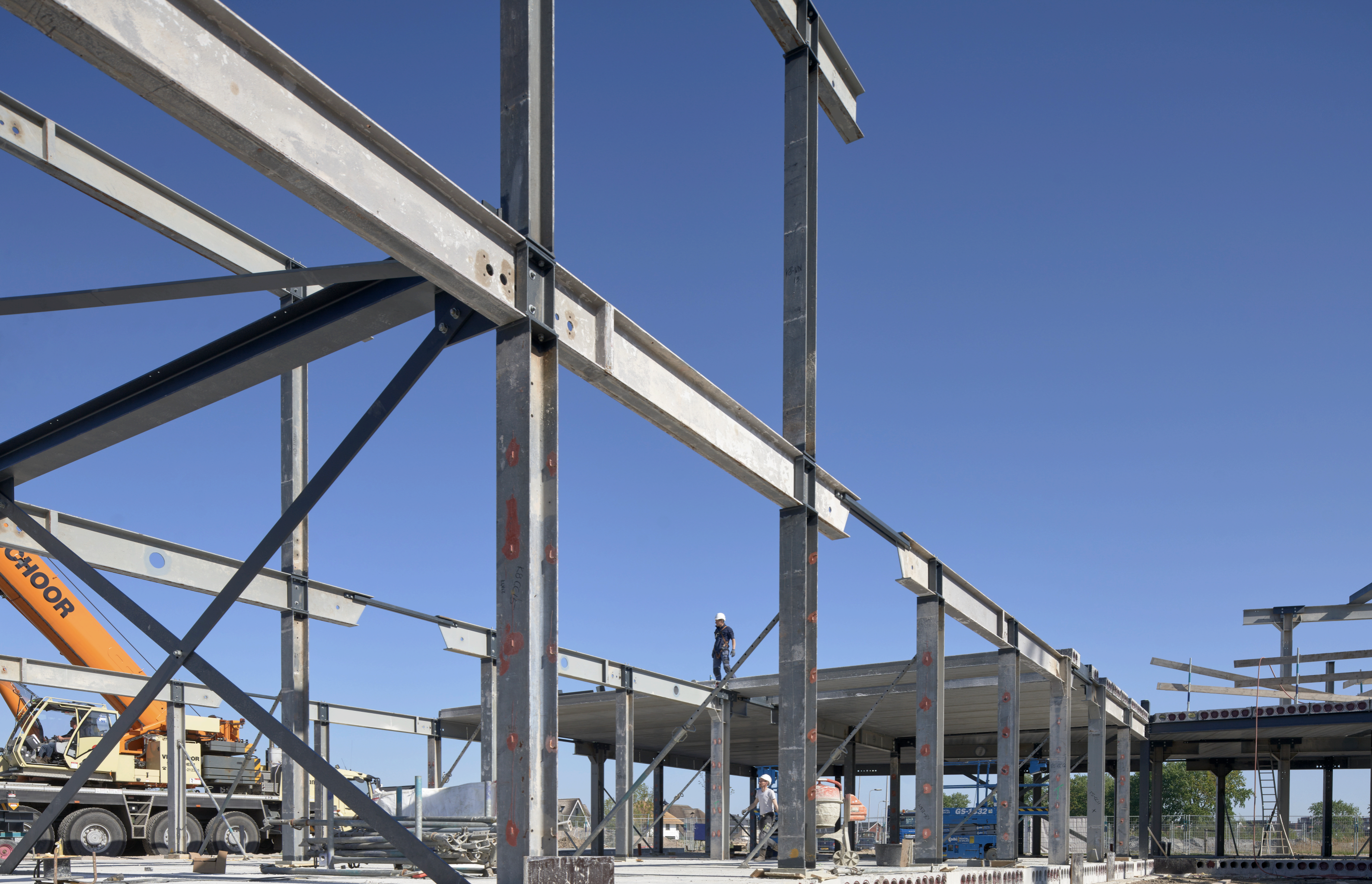

BioPartner5 - NETHERLANDS

Project owner

BioPartner Center Leiden

Engineer

IMd Raadgevende Ingenieurs

Architect

Popma ter Steege Architecten

General Contractor

De Vries en Verburg, Stolwijk

Steelwork Contractor

Vic Obdam Staalbouw

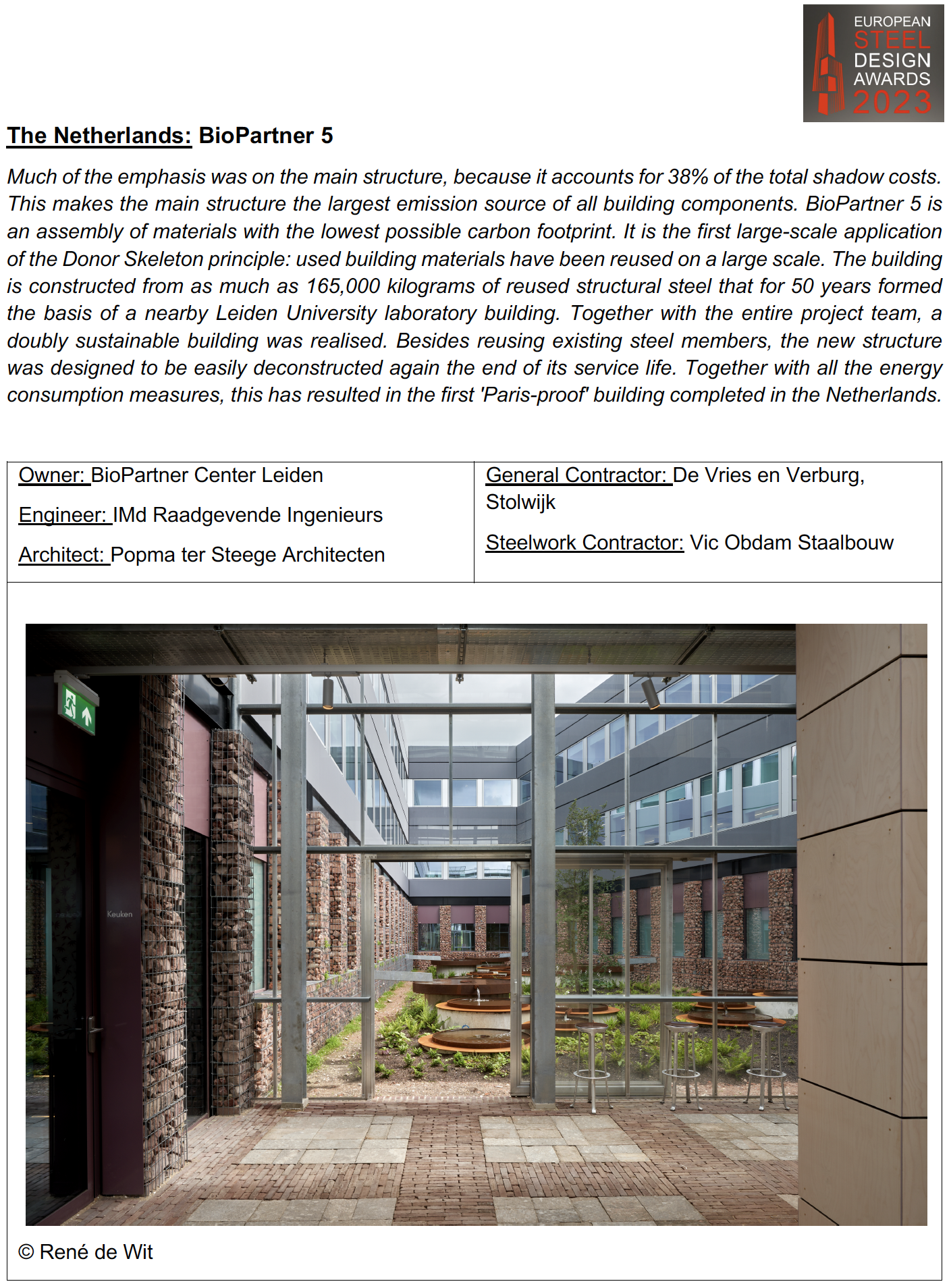

Much of the emphasis was on the main structure, because it accounts for 38% of the total shadow costs. This makes the main structure the largest emission source of all building components. BioPartner 5 is an assembly of materials with the lowest possible carbon footprint. It is the first large-scale application of the Donor Skeleton principle: used building materials have been reused on a large scale. The building is constructed from as much as 165,000 kilograms of reused structural steel that for 50 years formed the basis of a nearby Leiden University laboratory building. Together with the entire project team, a doubly sustainable building was realised. Besides reusing existing steel members, the new structure was designed to be easily deconstructed again the end of its service life. Together with all the energy consumption measures, this has resulted in the first 'Paris-proof' building completed in the Netherlands.

ESDA 2023 Special Award - Manufacturing:

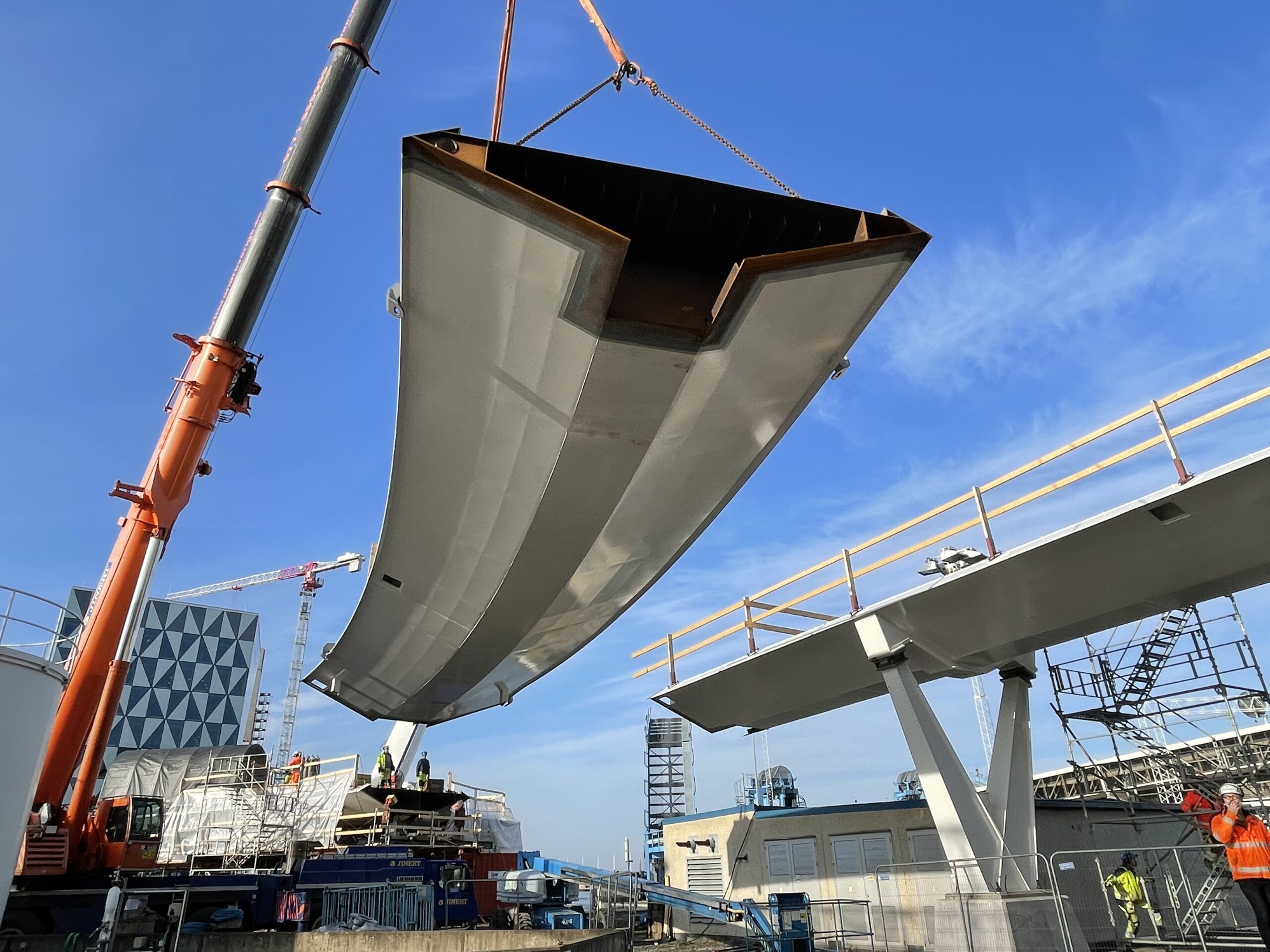

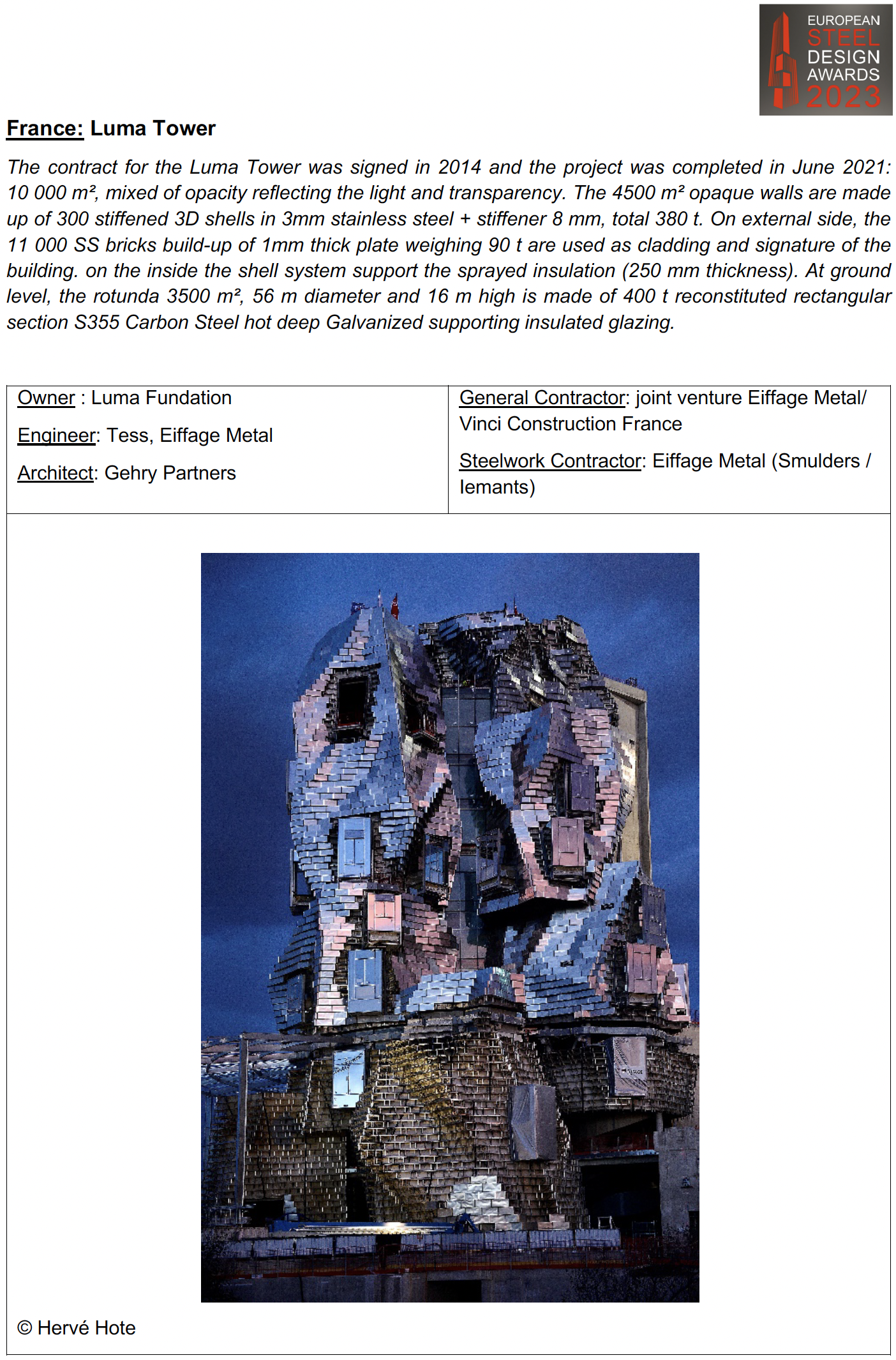

Luma Tower - FRANCE

Project owner

Luma Fundation

Engineer

Tess, Eiffage Metal

Architect

Gehry Partners

General Contractor

joint venture Eiffage Metal/ Vinci Construction France

Steelwork Contractor

Eiffage Metal (Smulders / Iemants)

The contract for the Luma Tower was signed in 2014 and the project was completed in June 2021: 10 000 m², mixed of opacity reflecting the light and transparency. The 4500 m² opaque walls are made up of 300 stiffened 3D shells in 3mm stainless steel + stiffener 8 mm, total 380 t. On external side, the 11 000 SS bricks build-up of 1mm thick plate weighing 90 t are used as cladding and signature of the building. on the inside the shell system support the sprayed insulation (250 mm thickness). At ground level, the rotunda 3500 m², 56 m diameter and 16 m high is made of 400 t reconstituted rectangular section S355 Carbon Steel hot deep Galvanized supporting insulated glazing.

ESDA 2023 Special Award - Integrated design:

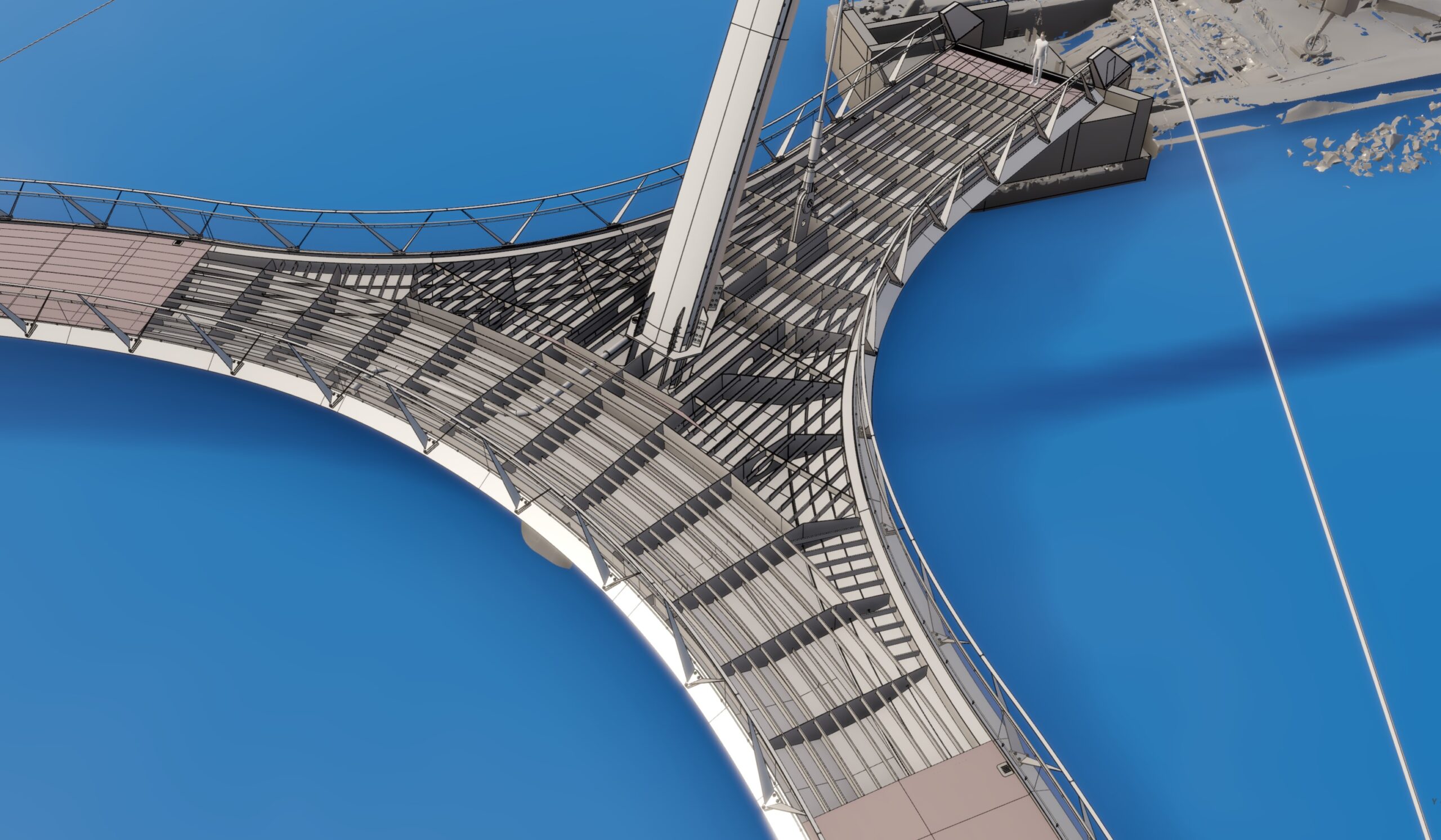

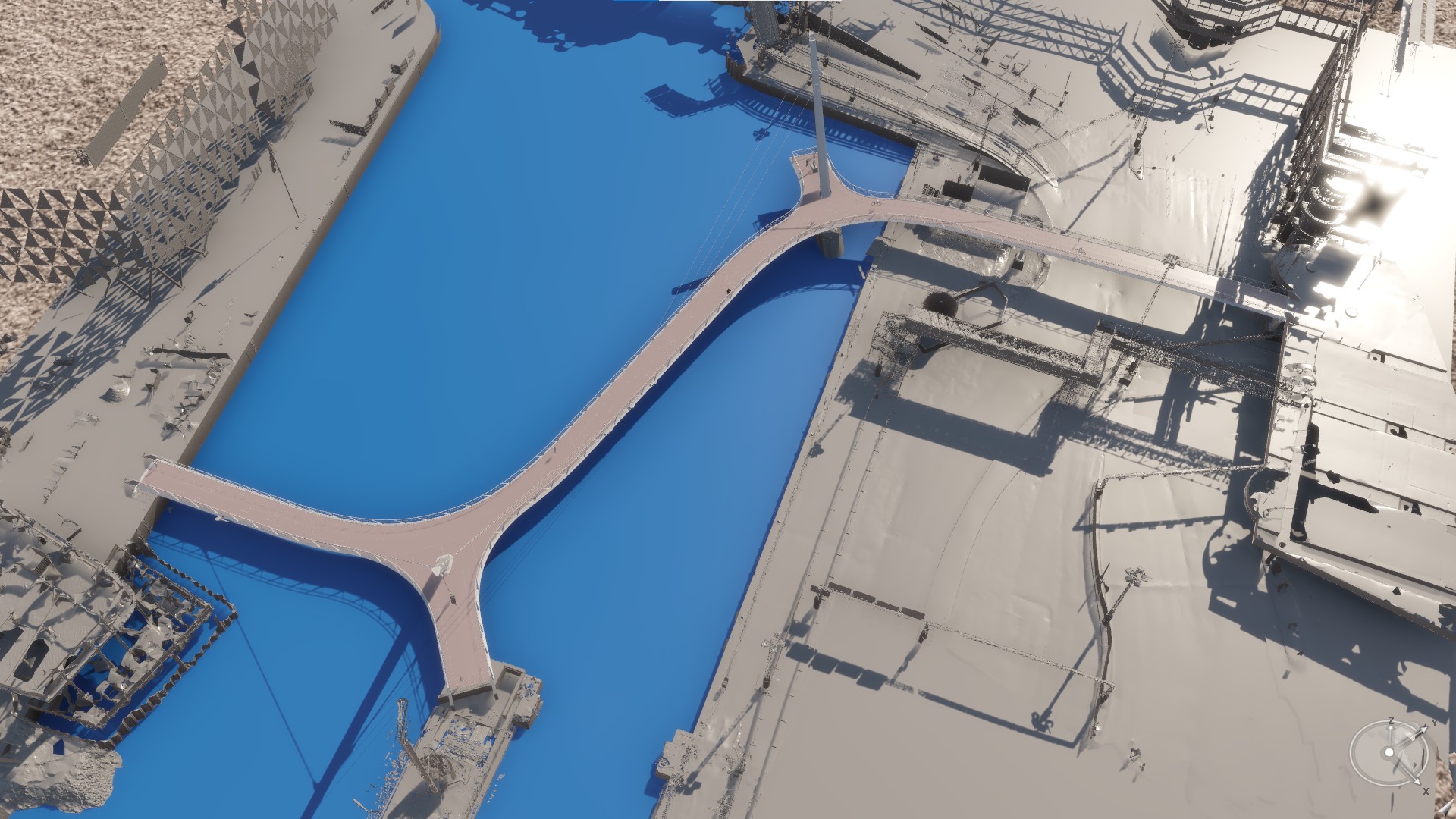

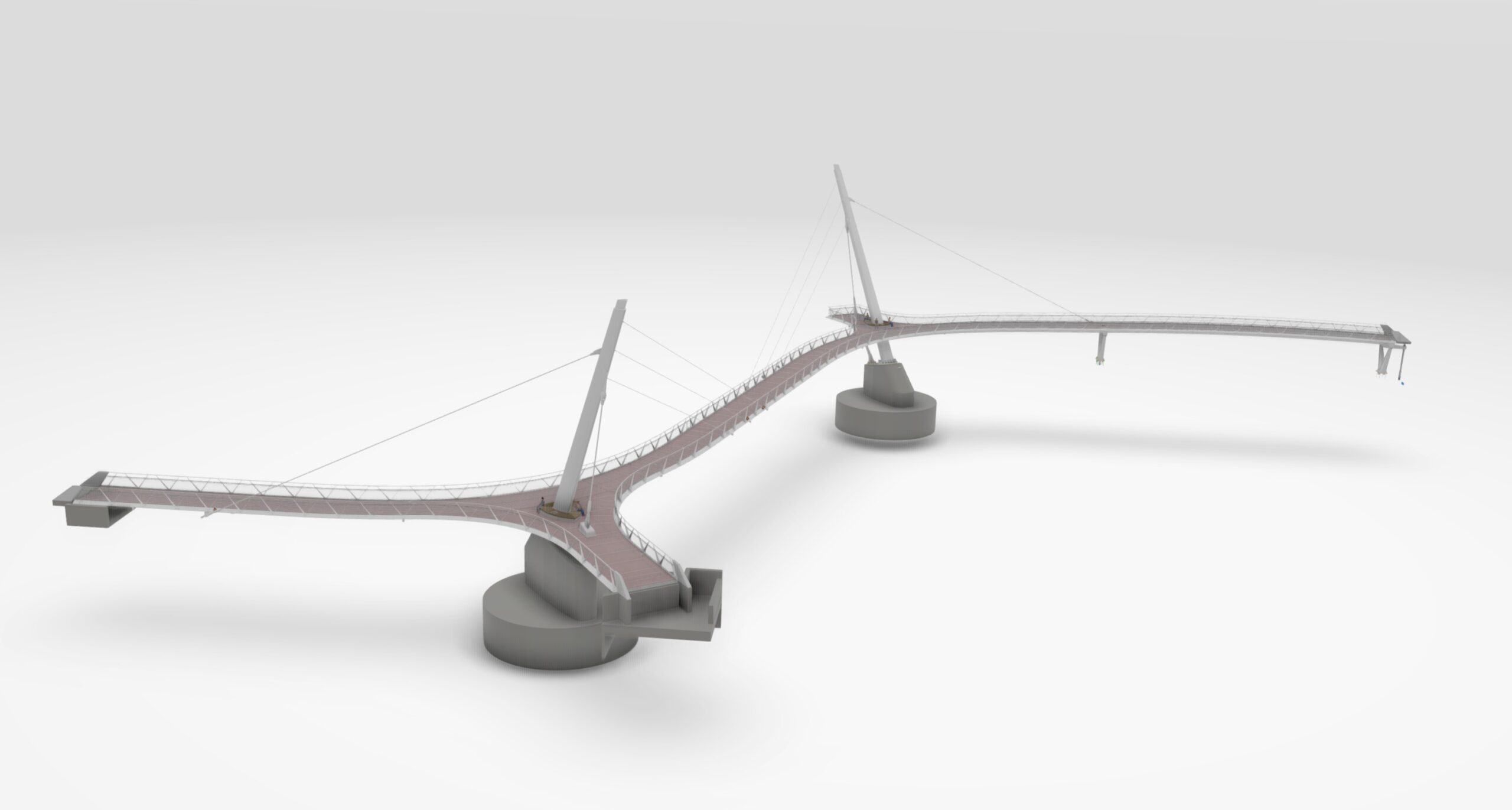

Varvsbron, Helsingborg (SWEDEN):

Project owner

Helsingborgs Stad (The City of Helsingborg)

Engineer

- Ramboll Sweden AB

- Centerlöf&Holmberg, Malmö

- Leonhardt, Andrä und Partner, Stuttgart

- Luxera AB, Malmö (Lighting design)

Architect

Ramboll Sweden AB/Ramboll UK

General Contractor

PEAB

Steelwork Contractor

Stål-och Rörmontage, Sölvesborg, Sweden

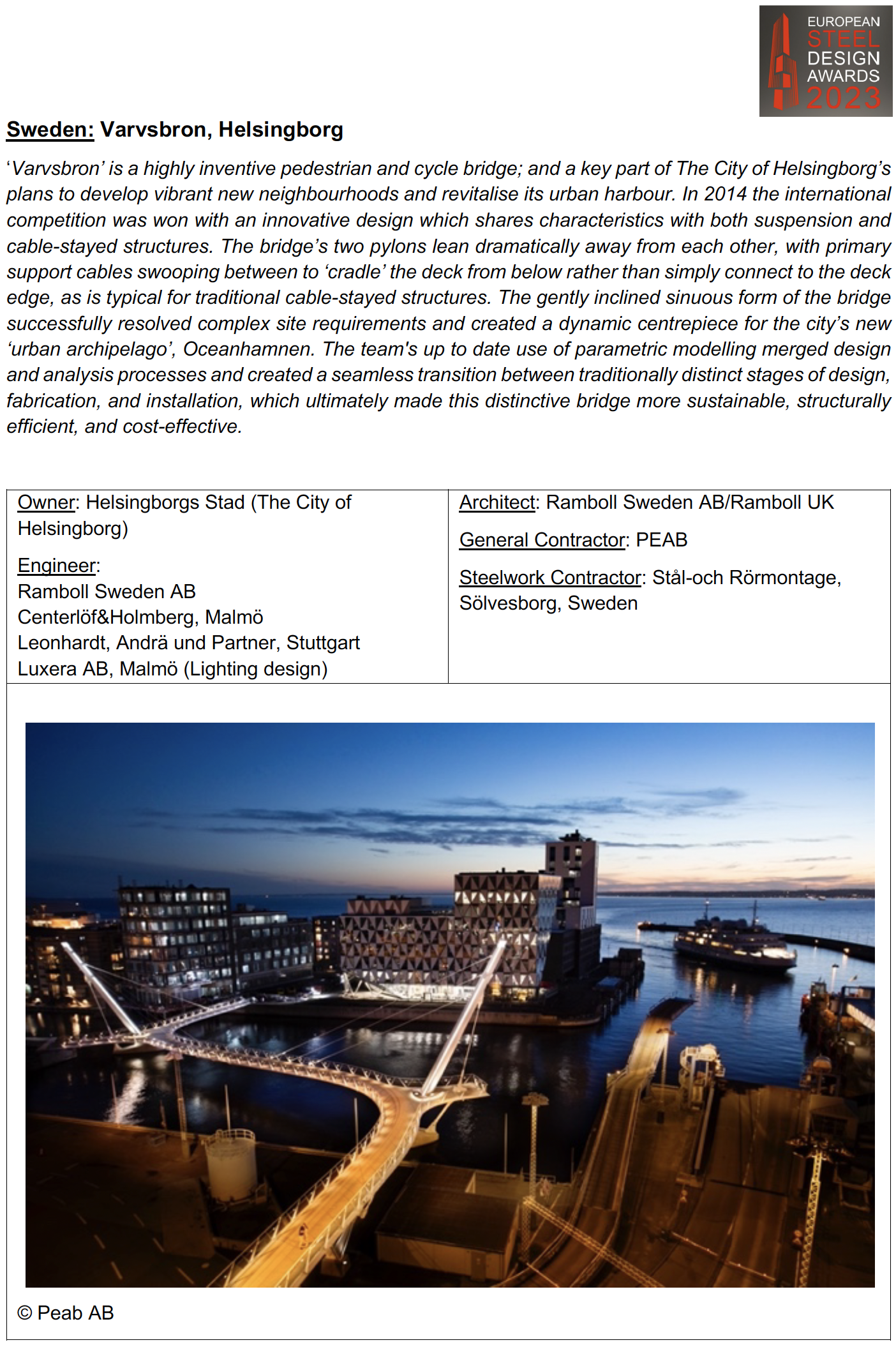

‘Varvsbron’ is a highly inventive pedestrian and cycle bridge; and a key part of The City of Helsingborg’s plans to develop vibrant new neighbourhoods and revitalise its urban harbour. In 2014 the international competition was won with an innovative design which shares characteristics with both suspension and cable-stayed structures. The bridge’s two pylons lean dramatically away from each other, with primary support cables swooping between to ‘cradle’ the deck from below rather than simply connect to the deck edge, as is typical for traditional cable-stayed structures. The gently inclined sinuous form of the bridge successfully resolved complex site requirements and created a dynamic centrepiece for the city’s new ‘urban archipelago’, Oceanhamnen. The team's up to date use of parametric modelling merged design and analysis processes and created a seamless transition between traditionally distinct stages of design, fabrication, and installation, which ultimately made this distinctive bridge more sustainable, structurally efficient, and cost-effective.

Professor J.M. ROTTER was born in Chesterfield, England and graduated at Cambridge University when he was awarded a Commonwealth Scholarship to study in Australia. He got a PhD in civil engineering from the University of Sydney. His main specialty is the Buckling of Shells.

Professor J.M. ROTTER was born in Chesterfield, England and graduated at Cambridge University when he was awarded a Commonwealth Scholarship to study in Australia. He got a PhD in civil engineering from the University of Sydney. His main specialty is the Buckling of Shells. Jouko KOUHI is expert in Connections, welding, stability and fatigue of steel structures. He has been an active member of various ECCS Technical Committees since 1979, working on ENV 1993 part 1.8 from 1999 to 2002.

Jouko KOUHI is expert in Connections, welding, stability and fatigue of steel structures. He has been an active member of various ECCS Technical Committees since 1979, working on ENV 1993 part 1.8 from 1999 to 2002. Frans BIJLAARD, Professor of steel structures at the Faculty of Civil Engineering & Geosciences at Delft University of Technology. His main specialties are on stability of steel structures, structural behaviour of joints in steel structures and design of greenhouses.

Frans BIJLAARD, Professor of steel structures at the Faculty of Civil Engineering & Geosciences at Delft University of Technology. His main specialties are on stability of steel structures, structural behaviour of joints in steel structures and design of greenhouses. The involvement of Professor Jean Pierre MUZEAU in Education and his strong motivation in promoting the use of steel in construction over his career have to be underlined. He has been qualified as “Passeur de Connaissances” (Ndt : conveyor of knowledge) by the Members of the Jury who have underlined his prominent role among the young generations of civil engineers.

The involvement of Professor Jean Pierre MUZEAU in Education and his strong motivation in promoting the use of steel in construction over his career have to be underlined. He has been qualified as “Passeur de Connaissances” (Ndt : conveyor of knowledge) by the Members of the Jury who have underlined his prominent role among the young generations of civil engineers. Prof. Joachim LINDNER got a 40-year academic career and extensive experience in civil engineering from lateral torsional buckling through contact splices, historical grey cast iron columns, fatigue behaviour, stability design of glass-beams, scaffolding design, crane girders, plate buckling problems, composite beams and columns, corrugated webs, connection problems and imperfection regulations. He signed around 220 publications.

Prof. Joachim LINDNER got a 40-year academic career and extensive experience in civil engineering from lateral torsional buckling through contact splices, historical grey cast iron columns, fatigue behaviour, stability design of glass-beams, scaffolding design, crane girders, plate buckling problems, composite beams and columns, corrugated webs, connection problems and imperfection regulations. He signed around 220 publications. Professor Reidar BJORHOVDE has an impressive academic background, including two Ph.D. in the area of Civil Engineering, and a remarkable professional career which includes several years as a Professor in various universities in North America. He also been the Director of Bjorhovde Group since 1998.

Professor Reidar BJORHOVDE has an impressive academic background, including two Ph.D. in the area of Civil Engineering, and a remarkable professional career which includes several years as a Professor in various universities in North America. He also been the Director of Bjorhovde Group since 1998.

Professor Carlo URBANO has been active on ECCS committee “Stability of steel structures” since 1975. He has been also present on CEN, IABSE, SSRC committees. Graduated at the Politecnico di Milano in 1963, he dedicated his career to the “Strength of Materials”. He developed scientific research mainly on the general theory of elasticity, stability of elastic equilibrium, response to dynamics and elastoplastic vibrations, shell structures, solutions for steel and reinforced structures. Lately, he has focused his works on the elastic and elastoplastic stability of compressed simple or composed steel members in the presence of mechanical and geometrical imperfections and damages due to cyclic actions. He is the author of an incredible number of papers and publications.

Professor Carlo URBANO has been active on ECCS committee “Stability of steel structures” since 1975. He has been also present on CEN, IABSE, SSRC committees. Graduated at the Politecnico di Milano in 1963, he dedicated his career to the “Strength of Materials”. He developed scientific research mainly on the general theory of elasticity, stability of elastic equilibrium, response to dynamics and elastoplastic vibrations, shell structures, solutions for steel and reinforced structures. Lately, he has focused his works on the elastic and elastoplastic stability of compressed simple or composed steel members in the presence of mechanical and geometrical imperfections and damages due to cyclic actions. He is the author of an incredible number of papers and publications.

Prof. Ing. Jean-Baptiste SCHLEICH will always be recognised as "Mr Fire” of Europe. He was the leading professor in the development of the "Natural Fire Safety Concept". Under his leadership, the relationship of the fire load to the risk to a structure and its occupants was researched and tested. It is due to his work that structures can now be fire engineered with a significant benefit to the industry, building owners and users.

Prof. Ing. Jean-Baptiste SCHLEICH will always be recognised as "Mr Fire” of Europe. He was the leading professor in the development of the "Natural Fire Safety Concept". Under his leadership, the relationship of the fire load to the risk to a structure and its occupants was researched and tested. It is due to his work that structures can now be fire engineered with a significant benefit to the industry, building owners and users. Professor Manfred HIRT had been member of the various ECCS Technical Committees. He wrote more than 130 publications as author or co-author. Director of the Steel Structures Laboratory (ICOM) of the Swiss Federal Institute of Technology at Lausanne (EPFL), Prof. Hirt was known on the international scene for his expertise in the field of fatigue and fracture mechanics of steel structures, loads and action on structures, structural safety and serviceability and steel-concrete composite construction. In August 2003, he had been elected President of the International Association for Bridge and Structural Engineering (IABSE).

Professor Manfred HIRT had been member of the various ECCS Technical Committees. He wrote more than 130 publications as author or co-author. Director of the Steel Structures Laboratory (ICOM) of the Swiss Federal Institute of Technology at Lausanne (EPFL), Prof. Hirt was known on the international scene for his expertise in the field of fatigue and fracture mechanics of steel structures, loads and action on structures, structural safety and serviceability and steel-concrete composite construction. In August 2003, he had been elected President of the International Association for Bridge and Structural Engineering (IABSE). Professor Giulio BALLIO was born in Rome, on 4 March 1940, and graduated in Aeronautical Engineering at the “Politecnico of Milan”, in 1963. He was Ordinario of the Science of Construction at Pavia University and, subsequently, of Construction in Steel at the Politecnico of Milan, where he has also been responsible, since 1985, for the Material Tests Laboratory.

Professor Giulio BALLIO was born in Rome, on 4 March 1940, and graduated in Aeronautical Engineering at the “Politecnico of Milan”, in 1963. He was Ordinario of the Science of Construction at Pavia University and, subsequently, of Construction in Steel at the Politecnico of Milan, where he has also been responsible, since 1985, for the Material Tests Laboratory. Prof. Dr.-Ing. Gerhard SEDLACEK, was a leading and opinion-forming person in various ECCS technical committees and subcommittees. He was one of the most active person in the European steel research sector as well as in the European codification field. His various activities covered a huge range beginning from intelligent design of steel and composite structures to researching, applying of research results, safety requirements, teaching and training of students and engineers, promotion and developing of steel structures and design tools for a better market share.

Prof. Dr.-Ing. Gerhard SEDLACEK, was a leading and opinion-forming person in various ECCS technical committees and subcommittees. He was one of the most active person in the European steel research sector as well as in the European codification field. His various activities covered a huge range beginning from intelligent design of steel and composite structures to researching, applying of research results, safety requirements, teaching and training of students and engineers, promotion and developing of steel structures and design tools for a better market share. Professor Patrick DOWLING started his working life as an employee of BCSA and subsequently worked both in industry and academia. He was extensively involved with ECCS in plate buckling research and was Chairman of the CEN Eurocode 3 Committee.

Professor Patrick DOWLING started his working life as an employee of BCSA and subsequently worked both in industry and academia. He was extensively involved with ECCS in plate buckling research and was Chairman of the CEN Eurocode 3 Committee. When awarded, Professor Federico MAZZOLANI was Director of the “Institute of Technique of Construction” at the Engineering Faculty of Naples, Italy. Born in Milan, in 1938, and graduated in Civil Engineering at the University of Naples, Prof. Federico M. Mazzolani co-operated since 1970 with ECCS, assuming the responsibility of Committee chairmanship. His activity has been characterised by the issue of several fundamental documents, which played a leader role in the development of the European codification at the level of both national codes and Eurocodes.

When awarded, Professor Federico MAZZOLANI was Director of the “Institute of Technique of Construction” at the Engineering Faculty of Naples, Italy. Born in Milan, in 1938, and graduated in Civil Engineering at the University of Naples, Prof. Federico M. Mazzolani co-operated since 1970 with ECCS, assuming the responsibility of Committee chairmanship. His activity has been characterised by the issue of several fundamental documents, which played a leader role in the development of the European codification at the level of both national codes and Eurocodes. Scientific Manager and Deputy General Manager of the French Technical and Industrial Centre of Steel Construction (CTICM), Professor Jacques BROZZETTI contributed highly to the development of the European Steel Construction. He had a long involvement with various research projects including stability problems, composite construction, fatigue and fire behaviour of steel structures. As a result, he had been involved with many Codes and design guides comprising writing activities. He worked with the profession to promote the steel construction on its various aspects.

Scientific Manager and Deputy General Manager of the French Technical and Industrial Centre of Steel Construction (CTICM), Professor Jacques BROZZETTI contributed highly to the development of the European Steel Construction. He had a long involvement with various research projects including stability problems, composite construction, fatigue and fire behaviour of steel structures. As a result, he had been involved with many Codes and design guides comprising writing activities. He worked with the profession to promote the steel construction on its various aspects. Prof. Jan W.B. STARK, from the University of Delft, The Netherlands, had made substantial contributions to the construction industry in general, and more specifically with regard to steel and composite structures. For many years, he had been an active member of CEN and served ECCS in various committees. The Charles Massonnet Award was presented to him to express our gratitude for his high standard and valuable contribution to the steel construction industry.

Prof. Jan W.B. STARK, from the University of Delft, The Netherlands, had made substantial contributions to the construction industry in general, and more specifically with regard to steel and composite structures. For many years, he had been an active member of CEN and served ECCS in various committees. The Charles Massonnet Award was presented to him to express our gratitude for his high standard and valuable contribution to the steel construction industry. Close collaborator of Professor Charles Massonnet, Professor René MAQUOI, was awarded in recognition of his efforts for the development of steel and composite construction. Indeed, Professor Massonnet was his “master” and conducted his first step in the ECCS activities.

Close collaborator of Professor Charles Massonnet, Professor René MAQUOI, was awarded in recognition of his efforts for the development of steel and composite construction. Indeed, Professor Massonnet was his “master” and conducted his first step in the ECCS activities.

Frantisek Wald concentrates on the connection and fire design of steel structures. He prepared the component model for column bases and the component based finite element model of joints. He works in ECCS Technical Committee 10 - Structural joints and in Project team for preparation of standard - EN 1993-1-8:2020.

Frantisek Wald concentrates on the connection and fire design of steel structures. He prepared the component model for column bases and the component based finite element model of joints. He works in ECCS Technical Committee 10 - Structural joints and in Project team for preparation of standard - EN 1993-1-8:2020.